"...through the OARnet connection, we have already demonstrated that we can operate those microscopes from tens or even hundreds of miles away."

—David McComb, director of Center for Electron Microscopy and AnalysiS at The Ohio State University

AS IF IT ISN'T AMAZING ENOUGH that the researchers at an Ohio State University lab can peer into the atomic-level workings of structural materials and biological systems, they are now operating their electron microscopes from the next room and are studying how they could leverage OARnet connectivity to do the same work from the next university or, eventually, the next continent.

The goal for the Center for Electron Microscopy and AnalysiS (CEMAS) is to “amplify what is possible” in the characterization of materials using multimillion-dollar electron microscopes. The center’s director envisions the lab as a hub for world-class characterization of materials research across all disciplines, from medicine and life sciences to engineering and physical sciences and everything in between.

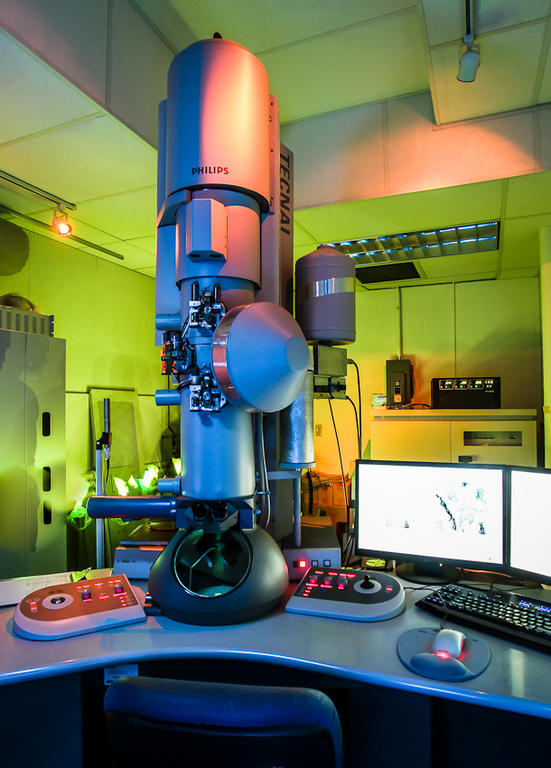

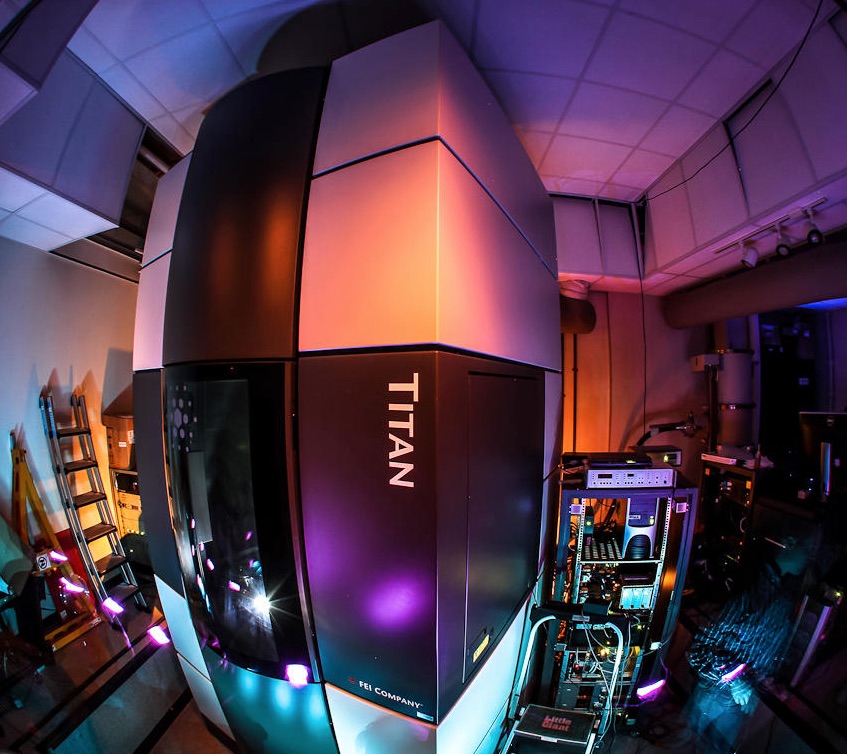

Opening on Ohio State’s west campus in 2013, the 20,000-square-foot center includes two electron microscopes from the Titan line—the world's most powerful, commercially available microscopes—that are optimized to perform analysis on the atomic scale. Three additional transmission electron microscopes (TEMs), plus two dual-beam focused ion beam (FIB) instruments and three scanning electron microscopes (SEMs) also are available to researchers.

“As we have created CEMAS to be one of the top centers in the world, we also have shouldered the responsibility to ensure that these capabilities are available to researchers not only at The Ohio State University, but indeed to researchers across the entire region, the nation and, to some extent, eventually the world,” said David McComb, Ph.D., an Ohio Research Scholar and professor of materials science and engineering at Ohio State. “Obviously people can travel to the center and work with us, but a big opportunity that we saw in creating the center was leveraging our connection to OARnet to enable these facilities to be used remotely.”

Thanks to OARnet’s fiber-optic, 10-Gigabit-per-second (Gbps) connection from the lab to the network’s 100 Gbps ultra-fast statewide backbone, any organization connected to OARnet’s network can purchase time and directly operate the instruments from a remote location with no perceptible delay.

CEMAS technicians currently have installed two remote stations, each about 60 miles from the microscopy center: one in the Air Force Research Lab at Wright-Patterson Air Force Base and another at the University of Dayton. Earlier this year, the Air Force lab purchased its first two electron microscopes, but scientists working there for the Materials and Manufacturing Directorate quickly recognized the benefit of augmenting their capabilities by also connecting to the far more sensitive instruments at CEMAS.

“The AFRL connection leverages a 10 Gbps fiber-optic link to the base between the OARnet backbone and the Defense Research and Engineering Network,” explained Dana Rogers, OARnet’s client representative for Ohio State and much of northwest Ohio.

“With our direct connection to OARnet, we have a shorter, simpler path to our remote stations since we’re not traversing a university network or the commercial Internet,” said Daniel Huber, a CEMAS technical officer, as well as a research engineer at the Center for the Accelerated Maturation of Materials. Huber has been working with OARnet and the Ohio Supercomputer Center to enhance remote microscopy techniques since helping to demonstrate the technology at an international supercomputing conference in 2006.

“Utilizing OARnet, it’s just a handful of hops – maybe three or four hops – from CEMAS to the station at the University of Dayton,” he said. “So we’re looking at a very, very low wait, maybe only three milliseconds – that’s almost the same delay you’ll have just inside of a facility.”

McComb recognizes that, from a funding-agency perspective, university labs at every single institution cannot continue to invest in instruments that can cost millions of dollars. The future is to place such instruments into institutions that have the infrastructure, the people and the support to optimize their performance for maximum impact.

“The people at NSF, OARnet and the Ohio Supercomputer Center, as well as ourselves, recognize that some development work and research needs to be done in order to deliver this,” McComb said. “But, it’s undoubtedly going to be the way forward, probably not just for electron microscopes, but for other types of high-end instrumentation.”